Product Description:

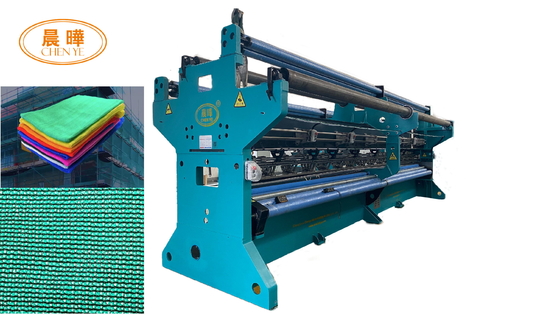

The Fishing Net Making Machine is an advanced piece of net-manufacturing equipment designed to revolutionize the production of fishing nets with remarkable efficiency and precision. Equipped with a state-of-the-art PLC control system, this net-making automaton offers users unparalleled control and automation, ensuring consistent quality and high productivity in every batch of nets produced.

At the heart of this net-forming device is a powerful electric power source that drives the entire operation smoothly and reliably. The machine operates at a speed ranging from 30 to 50 meters per minute, enabling rapid net production while maintaining exceptional accuracy and strength in the netting material. This speed range is ideal for meeting both small-scale and large-scale fishing net manufacturing demands, making the machine highly versatile and adaptable to various production needs.

One of the standout features of this fishing net making machine is its energy-efficient design. With a power consumption range of just 3kW to 10kW, it balances performance with cost-effectiveness, significantly reducing electricity expenses compared to traditional net-making methods. This low power consumption, combined with its electric power source, makes the machine environmentally friendly and suitable for continuous operation in industrial settings.

The new condition of the machine guarantees that users receive the latest technology and innovations in net-making automation. Being a brand-new net-manufacturing equipment, it comes with the latest advancements in mechanical design and control software, ensuring durability, minimal maintenance, and ease of use. This modern net-forming device is built with high-quality materials and components, ensuring long service life and consistent operational performance even under demanding production schedules.

The PLC control system integrated into this net-making automaton streamlines the manufacturing process by allowing precise adjustments to speed, tension, and net dimensions. This automation capability not only enhances the quality of the fishing nets produced but also reduces labor costs and the potential for human error. Operators can easily monitor and control the machine through an intuitive interface, making it accessible to both experienced technicians and newcomers in the fishing net industry.

In addition to its technical specifications, the fishing net making machine is designed with user safety and convenience in mind. Safety features are incorporated throughout the net-forming device to protect operators during operation, while its ergonomic design ensures comfortable handling and easy maintenance. The machine’s compact footprint allows it to be installed in various production environments without requiring excessive space, making it a practical choice for businesses looking to optimize their manufacturing facilities.

Overall, this fishing net making machine represents a significant advancement in net-manufacturing equipment, combining high-speed production, energy efficiency, and sophisticated automation to meet the evolving needs of the fishing industry. Whether producing nets for commercial fishing, aquaculture, or recreational purposes, this net-making automaton delivers superior performance and exceptional value, making it an indispensable asset for manufacturers seeking to enhance their production capabilities.

By investing in this new generation net-forming device, businesses can achieve higher output, improved product consistency, and reduced operational costs, all while benefiting from the latest technology in fishing net production. This machine exemplifies the future of net manufacturing, where automation and innovation come together to meet industry demands with excellence and reliability.

Applications:

The Chenye Fishing Net Making Machine, model number DRCP, is an advanced electric-powered net-forming device designed to meet the high demands of modern fishing industries. This net-weaving machine is engineered to efficiently produce durable fishing nets using round yarn, ensuring strength and longevity in various aquatic environments. Its fast and high production capabilities make it an indispensable tool for businesses aiming to increase output without compromising on quality.

Ideal for large-scale fishing net manufacturing facilities, the Chenye net-making automaton excels in delivering consistent and uniform nets, which are essential for commercial fishing operations. The machine’s electric power source ranges from 3kW to 10kW, providing sufficient energy to maintain high-speed operations while optimizing power consumption. This balance of power and efficiency ensures cost-effectiveness for manufacturers, making it suitable for continuous production cycles.

The Fishing Net Making Machine by Chenye is perfectly suited for various application occasions and scenarios. It is commonly used in factories specializing in fishing gear production, where the demand for robust and reliable nets is high. Additionally, it is an excellent choice for workshops focused on producing customized netting solutions for different fishing environments, including freshwater and marine settings. The machine’s versatility allows it to handle different sizes and types of round yarn, catering to diverse fishing requirements.

Moreover, the net-forming device is highly beneficial in regions with a strong fishing culture where local enterprises need efficient machinery to boost their production capacity. Its user-friendly design and automated features reduce the need for extensive manual labor, making it ideal for operators seeking to streamline their manufacturing processes. The Chenye net-weaving machine also finds applications in research and development centers working on innovative fishing net designs and materials.

In summary, the Chenye DRCP Fishing Net Making Machine is a powerful and reliable net-making automaton designed for high-speed production of quality fishing nets. Its electric power source, combined with advanced net-forming technology and adaptability to round yarn, makes it suitable for a wide range of industrial and commercial fishing net manufacturing scenarios. Whether in large factories, small workshops, or R&D facilities, this machine delivers efficiency and excellence in net production.

Customization:

Chenye's DRCP model Fishing Net Machine offers exceptional product customization services tailored to meet your specific net manufacturing needs. Designed to operate efficiently within a temperature range of -10°C to 50°C, this net-forming device utilizes high-quality round yarn to produce durable and reliable fishing nets. With a gauge range from E3 to E18, the machine allows for versatile net sizes and mesh specifications, accommodating different size dimensions as per your requirements.

As a leading net-manufacturing equipment, the Chenye DRCP model ensures precision and consistency in every net produced. Our customization services include adjustments in gauge, yarn type, and machine dimensions to perfectly align with your production goals. Whether you need a compact setup or a larger configuration, this net-manufacturing equipment can be tailored to suit your operational environment and output demands.

Choose Chenye’s Fishing Net Machine for a customizable net-forming device that enhances efficiency and quality in your fishing net production process.

Support and Services:

Our Fishing Net Making Machine is designed to provide efficient and reliable performance for all your net production needs. To ensure optimal operation, please follow the guidelines below.

Installation and Setup:

Carefully unpack the machine and place it on a stable, level surface. Connect the power supply according to the specifications provided in the user manual. Make sure all components are securely attached before starting the machine.

Operation:

Before use, inspect the machine for any damage or loose parts. Load the appropriate netting material and adjust the settings according to the type and size of the net to be produced. Always operate the machine within the recommended speed and tension parameters to prevent damage and ensure quality output.

Maintenance:

Regular maintenance is essential for the longevity of the machine. Clean the machine after each use to remove any debris or residue. Lubricate moving parts as indicated in the maintenance schedule. Periodically check for worn or damaged components and replace them promptly to avoid breakdowns.

Troubleshooting:

If the machine experiences operational issues, refer to the troubleshooting section of the user manual. Common problems include thread breakage, uneven netting, and motor overheating. Address these issues by adjusting machine settings, checking material quality, or allowing the motor to cool down as needed.

Warranty and Support:

The Fishing Net Making Machine comes with a limited warranty covering manufacturing defects. For technical support, maintenance services, and spare parts, please refer to the service section in the manual. Our team is committed to assisting you in maximizing the performance and lifespan of your machine.

For detailed instructions and safety information, always refer to the user manual provided with your Fishing Net Making Machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!