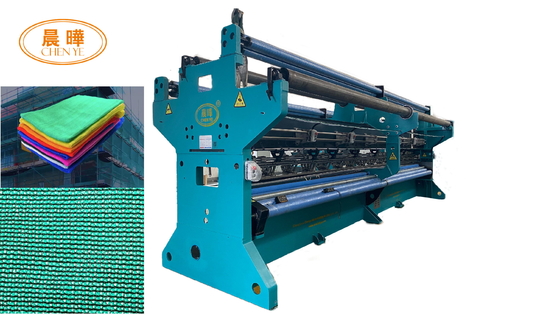

Shade Cloth Warp Knitting Sunshade Net Manufacturing Machine For Agricultural net

Product Description:

Number of bar : 2~8

Working Width : 135", 150", 170", 220", 240". 260"

Take-up manner: 2 rollers with friction drive, center shaft drive, 2 rollers with friction drive, separately-standing, center shaft drive, separately-standing

Feature:The machine is equipped with oiled eccentric gearing and the negative yarn let-off system.

Needle Type:Block latch needle ,individual latch needle or Compound needle

Gauge : E3,E6,E7,E8,E9,E12,E14,E16,E18

Machine Parameters:

| Type |

Size(L×W×H) |

Weight(Kg) |

Power(KW) |

Speed(rpm) |

| Main motor |

Inching motor |

| SRCA-135 |

4300×2200×2700 |

4700 |

3 |

0.37 |

200-530 |

| SRCA-150 |

4900×2200×2700 |

5000 |

3 |

0.37 |

200-530 |

| SRCA-180 |

6100×2200×2700 |

7500 |

5.5 |

0.75 |

200-530 |

| SRCA-220 |

7300×2200×2700 |

9000 |

5.5 |

1.5 |

200-530 |

| SRCA-260 |

8200×2200×2700 |

11000 |

7.5 |

1.5 |

200-480 |

| SRCA-340 |

10300×2200×2700 |

14000 |

11 |

1.5 |

200-450 |

Application:

Shade net is a type of netting material that is used to provide shade and protection from excessive sunlight. It is commonly used in agricultural settings, nurseries, gardens, and even in outdoor areas to create a cooler and more controlled environment.

Purpose

1.Protection from Sunlight: Shade nets are designed to reduce the intensity of sunlight, preventing crops, plants, or animals from overheating. They are often used to create a microclimate that is more favorable for growth.

2.Temperature Control: By filtering the sunlight, they help to maintain lower temperatures in the area they cover, making it more comfortable for plants, animals, or even people.

3.Wind and Dust Barrier: They can also act as a windbreak, reducing wind speed and preventing dust from blowing into sensitive areas.

Product Image:

Support and Services:

Shading Net Making Machine Technical Support and Service

Our company provides technical support and service for our Shading Net Making Machine. We offer a variety of services to help you get the most out of your machine. Technical support services include:

- Information and troubleshooting assistance

- Software and hardware upgrades

- Installation and maintenance services

- Technical advice and guidance

- Parts and accessories replacements

We also provide on-site service for complex repairs and maintenance. Our team of highly qualified and experienced technicians can help you with any technical problems you may have, or any adjustments you need to make to the machine. We are dedicated to providing the best possible customer service and support for our Shading Net Making Machine.

Packing and Shipping:

We will ensure the safety of the goods.

Shading Net Making Machine FAQ

1. What is the output of shading net making machine?

It’s according the machine working width and net technical,it is about 500-1000KG/24h.

2. How much space needed to set up a shading net production line?

A small-scale production line may require at least 100-200 square meters of space, while a larger production line may require several thousand square meters. It's important to consider the space needed for each machine, as well as space for storing raw materi ls and finished products.

3. How many kinds of shading net can be produced by rascheal warp knitting machine?

According the different material,There have four kinds of shade net can be produced,mono+mono yarn shading net, mono+flat yarn shading net,mono+flat yarn shade net,Al+pet yarn shade net.

4. Are the machines customizable for different net specifications?

Yes, modern shading net making machines are often customizable to produce nets of various sizes, mesh configurations, and materials. Adjustments can be made to the machine settings to meet specific shading requirements.

5. What types of shading nets material can be made with these machines?

In general ,shading net material is HDPE,less shading net use AL and PET material.

6. Are there any special skills required to operate the machine?

Operating a shading net making machine may require some training to ensure optimal performance. Manufacturers typically provide training sessions or manuals to guide operators through the setup, operation, and maintenance of the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!