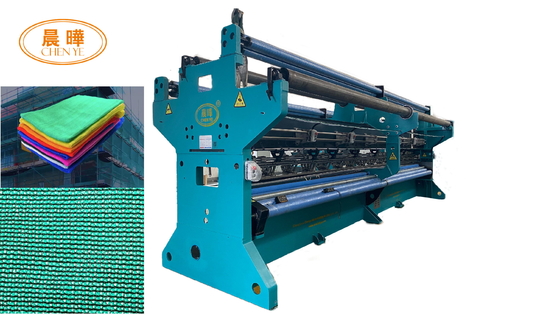

Fishing Net Making Machine

Product Properties:

| Brand |

Raschel |

Type |

Warp Knitting Machine |

| Speed |

200-600 |

Gauge |

E3,E6,E7,E8,E9,E12,E14 |

| Number of bars |

2-8 |

Needle Type |

Latch Needle |

Product Description:

High Speed Single Needle Bar Fishing Net Making Machine Raschel Machine

Application:

This machine is used to produce knotless fishing net, sports net ,purse net and deep sea aquaculture net and so on.

Features:

The machine is equipped with oiled eccentric gearing and the negative yarn let-off system.

This machine is used for weaving sports nets, protective nets and packaging nets and other fields.

Technical Parameters:

|

型号

Machine type

|

外型尺寸(长X宽X高)

Machine size

|

全机重量

(Kg)

Machine weight

|

全机重量电机功率(KW)Motor power |

转速speed(rpm)

(横列/分钟)

|

| 主电机Main motor |

慢动电机Inching molor |

| SROP-135 |

4300X2200X2700 |

约4700 |

3 |

0.37 |

200-600 |

| SROP-150 |

4900x2200x2700 |

约5000 |

4 |

0.37 |

200-600 |

| SROP-170 |

5800x2400x2800 |

约7500 |

5.5 |

0.75 |

200-600 |

| SROP-220 |

7300x2400x2800 |

约9000 |

5.5 |

1.5 |

200-600 |

| SROP-240 |

7600x2400x2800 |

约10500 |

5.5 |

1.5 |

200-600 |

| SROP-260 |

8100x2400x2800 |

约11000 |

7.5 |

1.5 |

200-600 |

Product Image:

Support and Services:

Fishing Net Making Machine Technical Support and Service

Our company provides technical support and service for our Fishing Net Making Machine. We offer a variety of services to help you get the most out of your machine. Technical support services include:

- Information and troubleshooting assistance

- Software and hardware upgrades

- Installation and maintenance services

- Technical advice and guidance

- Parts and accessories replacements

We also provide on-site service for complex repairs and maintenance. Our team of highly qualified and experienced technicians can help you with any technical problems you may have, or any adjustments you need to make to the machine. We are dedicated to providing the best possible customer service and support for our Fishing Net Making Machine.

Packing and Shipping:

We will ensure the safety of the goods.

Fishing Net Making Machine FAQ

1. What is the output of fishing net making machine?

It’s according the machine working width and net technical,it is about 500-1000KG/24h.

2. How much space needed to set up a fishing net production line?

The amount of space needed to set up a fishing net production line can vary depending on the size and complexity of the production line. generally, a production line for fishing nets requires 200m2.

3. What are the benefits of using a knotless fishing net making machine?

Using a fishing net making machine offers several advantages, including:

Increased Production: Machines work faster and can produce a larger volume of nets in a shorter time.

Consistency: Machine-produced nets have uniform quality and dimensions.

Reduced Labor: Automation reduces the need for manual labor, cutting down on workforce requirements.

Precision: Machines ensure accurate knotting and mesh spacing, improving net performance.

Cost-Efficiency: Over time, the machine's higher production output can lead to reduced production costs per net.

4. Are the machines customizable for different net specifications?

Yes, modern fishing net making machines are often customizable to produce nets of various sizes, mesh configurations, and materials. Adjustments can be made to the machine settings to meet specific fishing requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!