Product Description:

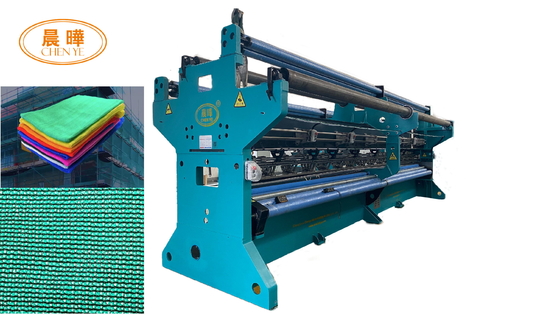

Raschel Knitting Machine DRCP

This machine is used for weaving sports nets, protective nets and packaging nets and other fields.

APPLICATION:This machine is used of the producing spots nets, safety nets and packing nets .

FEATURES: The machine is equipped with open cam gearing ,the negative yarn let-off system.

THE MAIN TECHNICAL SPECIFICATION:

✮ Needle Type: Block latch needle or individual latch needle

✮ Gauge: E4,E6,E9;

✮ Number of bars : 8

✮ Working Width: 130,190“,220“;

✮ Take-up Manner: Separately-standing take-up

✮ Relevant corollary equipment: Warping Machine

Technical Parameters:

The main technical specifications of this device are as follows:

✮ Needle Type: The device requires either block latch needles or individual latch needles.

✮ Gauge: E4, E6 or E9.

✮ Number of bars: This device has 8 bars.

✮ Working Width: The available working widths are 130, 190 and 220 inches.

✮ Take-up Manner: This device uses separately-standing take-up.

✮ Relevant corollary equipment: Warping machine and motor are required to use this device.

Applications:

The Double Needle Bar Raschel Machine (DRCP) application is a versatile tool used for a variety of purposes. It is especially useful for creating nets, such as sports nets, protective nets, and packaging nets.

This technology is particularly advantageous for sports purposes, where it is important to secure the netting in order to provide maximum safety. Moreover, protective nets can be created to cover dangerous areas, ensuring that the people or objects within them are kept secure. Packaging nets are equally useful for making sure that products are safe during distribution and delivery.

The DRCP is also utilized in other fields, such as for fishing nets or shading nets. In short, the versatility of this tool allows for a wide range of applications in various industries and sectors.

Support and Services:

Fishing Net Making Machine Technical Support and Service

Installation and Testing

We provide installation and testing services for our clients, to ensure that the Fishing Net Making Machine is correctly installed and working properly.

Repair and Maintenance

We provide repair and maintenance services for our Fishing Net Making Machine. Our technicians have extensive experience in troubleshooting and resolving any issue that may arise.

Training

We provide training services to our clients so that they can correctly operate and maintain our Fishing Net Making Machine.

Spare Parts

We provide a wide range of spare parts for our Fishing Net Making Machine. If any part of the machine becomes defective, we can quickly supply the necessary spare parts.

Packing and Shipping:

1. Usually 40HQ container is used for shipment, and the engineer plans the space inside the container reasonably.

2. Additional accessories will be shipped in standard wooden boxes to ensure that the accessories are complete and in good condition

3. To ensure that the machine can arrive at your factory smoothly: fix the machine with a standard specification steel wire rope to ensure that the machine will not move; use plastic film to fully cover and spray anti-rust special paint to prevent machine parts from being damaged and corroded during shipment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!