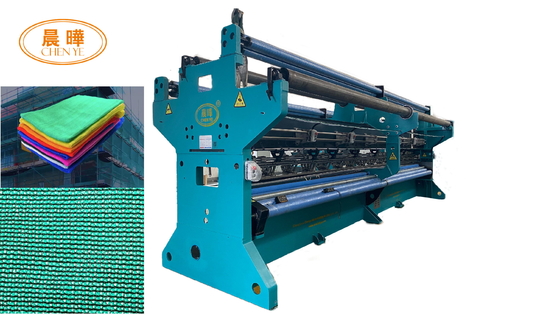

Product Description:

Raschel Knitting Machine DRCP Features

● The machine is durable, with long service life and stable operation;

●It can produce stronger and thicker multifilament mesh

● multi-bar 4-9;

● Simple operation and maintenance (daily maintenance, cleaning, simple needle replacement);

● EBA electronic warp let-off system, from mechanical to automatic, precisely controls the warp let-off amount, and the adjustment is more convenient.

Spindle speed measurement 400 rpm

decibel 80

Features:

Introducing the Raschel Knitting Machine DRCP - a machine that is designed for long-term use and stability. It features a multi-bar with 4, 5, 6, 7, 8, or 9 strands, and a spindle speed measurement of up to 400 RPM at a noise level of 80dB.

This machine can produce thicker and stronger multi-filament mesh with the use of a reliable electronic warp let-off system – for great convenience and precision. It also offers simple operation and maintenance: clean and change needles with ease and minimal effort.

Technical Parameters:

Our main technical specifications are outlined as follows:

- Needle Type: Block latch needle or individual latch needle

- Gauge: E4, E6, E9

- Number of bars: 8

- Working Width: 130, 190, 220 inches

- Take-up Manner: Separately-standing take-up

- Relevant corollary equipment: Warping Machine Weft Winder, etc.

Applications:

The Double Needle Bar Raschel Machine DRCP is a great application for producing nets for sports, protective, and packaging uses. The possibilities for usage of these nets are vast and can cover various fields.

For example, these nets could be used in sports such as soccer, lacrosse, hockey or badminton as dividers, backstops, cages, nets, or frames; in protective applications to safeguard pedestrians and products; and for packaging, such as bags and wraps.

The Double Needle Bar Raschel Machine DRCP provides a robust, durable and reliable solution for producing nets for a wide range of applications.

Support and Services:

Fishing Net Making Machine Technical Support and Service

We are committed to providing world-class technical support and service for Fishing Net Making Machine. Our knowledgeable and experienced support team is available to help you with any questions or problems you may have.

- 24/7 telephone support and online chat support

- On-site service and maintenance

- Software and hardware upgrades

- Troubleshooting and problem-solving

- Repair and replacement of parts

We are dedicated to helping you get the most out of your Fishing Net Making Machine. If you have any questions or need assistance, please don't hesitate to contact us.

Packing and Shipping:

1. Usually 40HQ container is used for shipment, and the engineer plans the space inside the container reasonably.

2. Additional accessories will be shipped in standard wooden boxes to ensure that the accessories are complete and in good condition

3. To ensure that the machine can arrive at your factory smoothly: fix the machine with a standard specification steel wire rope to ensure that the machine will not move; use plastic film to fully cover and spray anti-rust special paint to prevent machine parts from being damaged and corroded during shipment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!