Trusted shade net machine manufacturer

Chenye Provides the most reliable and most affordable shading Net Machine, We have 26 years experience of raschel knitting machine, developed the highest quality agro net manufacturing machine and manufactured the shade Net Warp Knitting Machine with the best shading effect. We export shading net machine to India,Turkey,Iran,Spain etc...with good customer feedback and reputation.

PRODUCT DESCRIPTION

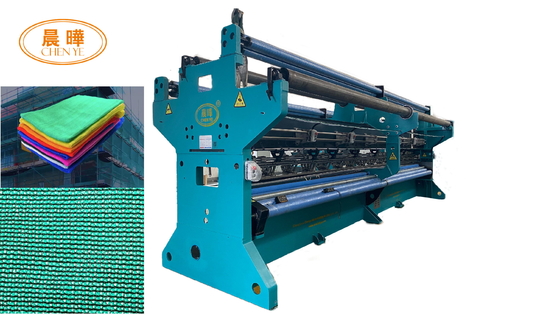

RS High Speed Single Needle Bar Raschel Machine

FEATURES:The machine is equipped with open cam gearing and 3-rollers positive yarn left-off system.

Usage:This machine is used to produce knotless fishing net,protecting net ,purse net,garment net and shading net.

Needle Type:Compound needle,Latch Needle

Gauge:E1,E2,E3,E6, E9, E12, E18,E24

Bar Number:2~4

Nominal Width:135" 150" 180" 220" 260"

| ype |

Size(L×W×H) |

Weight(Kg) |

Power(KW) |

Speed(rpm) |

| Main motor |

Inching motor |

| RS-130 |

4300×2200×2700 |

4500 |

3 |

0.37 |

400-700 |

| RS-150 |

4900×2200×2700 |

5000 |

3 |

0.37 |

400-700 |

| RS-180 |

6100×2200×2700 |

7500 |

5.5 |

0.75 |

400-650 |

| RS-220 |

7300×2200×2700 |

9000 |

5.5 |

1.5 |

400-650 |

| RS-260 |

8200×2200×2700 |

11000 |

7.5 |

1.5 |

400-650 |

| RS-340 |

10300×2200×2700 |

14000 |

11 |

1.5 |

400-650 |

MACHINE PICTURE

This machine can produce different sun screens according to different raw materials. It is widely used. Can produce sunshade and other products

APPLICATION

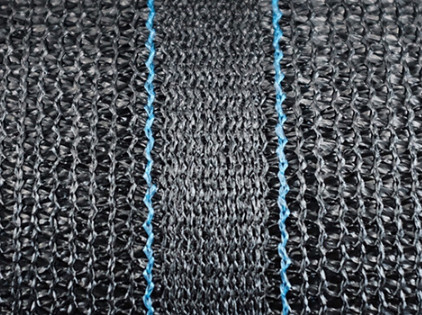

NET SPECIFICATION/SAMPLE

| material |

HDPE(high-density polyethylene) |

| Color |

white, green, blue, sand, black etc |

| Shade Rate |

35% - 95% |

| Type |

Warp Knitted |

| Useful life |

2 - 8 years |

| UV |

1%-5% |

Shade Nets For Agriculture FAQs

1. What is agro net?

It is a woven or knitted plastic material that allows only a certain amount of sunlight to pass through to the crop.

2. Why are shade nets important?

Because they provide protection to a crop from excessive radiation and heat. They help the crop to retain moisture and grow vigorously, without any water loss stress.

3. Are you manufacturer or trading company?

We are a specialized manufacturer.

4. Is your machine automatic or manual ?

Automatic.

5. How do you control the quality?

Professional QC team comply with TQM insure you the quality. Each step is in compliance to the standards. At the same time, we will take photos or shoot video for you.

6. What is the machine warranty?

One Year.

7. How long is the delivery time?

It's about 60 days.

8. Do you provide customized?

Sure, we can design the equipment according to the data of the structural section you provide. We are professional sheet metal forming machine designer and manufacturer

SERVICE

1.A full factory planning solution

2.24 hours online service

3.Employee training:We accept staffs and workers on-site training

4.Accept special net samples to develop customized business

5.After-sales service of machines:The manufacturer is responsible for installation training

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!