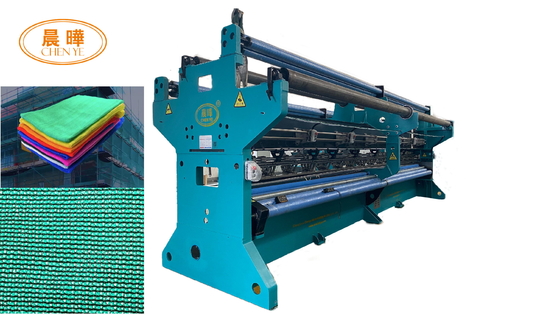

Doing a good job in the daily maintenance of the warp knitting machine, so that the machine can create higher value.

When the warp knitting machine is working, the parts of the machine will have subtle changes. In the long run, various problems will arise. Therefore, it is necessary to carry out appropriate maintenance on various parts.Only in that way can prevent the occurrence of various problems, so the relevant rules and regulations for daily maintenance of warp knitting machines should be implemented as soon as possible to promote the stable development of enterprises.

The daily maintenance of warp knitting machine generally includes the following three aspects:

1. Add various greases or lubricating greases to each specific friction component on time to reduce component damage and save output power. There are many rolling friction components on the warp knitting machine, such as the reciprocating sliding of the triangular seat in the slide rail and the left and right sliding of the knitting needle in the needle groove. This sliding not only consumes a lot of driving force, but also accelerates the damage of components and endangers the service life of the equipment. Therefore, in order to ensure the safe operation of the equipment, all normal production, and reduce labor intensity and power, it is very important to customize the inspection and lubricating oil.

2. Adjustment of the characteristics of the coil spring of the lead frame, the smoothness of each wire of the lead frame according to the hole, the equipment status and damage of the carbon brush, the equipment status and damage of the yarn feeder, all the normal conditions of the components on the surface of the triangular seat, each Proper condition and damage of a circled triangle, adjustment and damage of the triangle seat adjustment iron.

3. If there is no problem with the on-site and debugging of the warp knitting machine, the noise of the machine is not easy to be large during normal operation. Most of the noise problems in the middle and late stages are caused by poor maintenance, and the problem of the machine is not immediately solved.

The above are some suggestions for the daily maintenance of warp knitting machines summarized by the manufacturer.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!