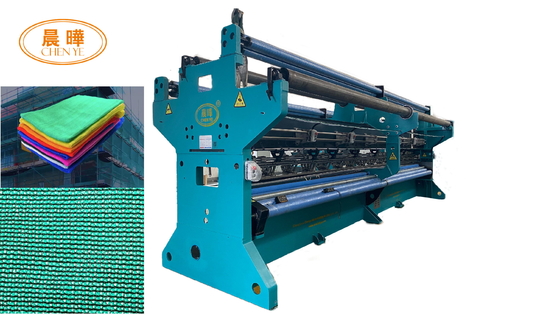

High Speed Fishing Crab Net Making Machine Knotless Fish With 1 Year Support

Product Description:

Raschel Knitting Machine DRCP Features

Application:

This machine is used to produce knotless fishing net, sports net ,purse net and deep sea aquaculture net and so on.

Features:

The machine is equipped with oiled eccentric gearing and the negative yarn let-off system.

This machine is used for weaving sports nets, protective nets and packaging nets and other fields.

Technical Parameters:

The main technical specifications of this equipment are as follows:

✮ Needle Type: The equipment is available with either a block latch needle or individual latch needle.

✮ Gauge: The gauge size options are E4, E6, and E9.

✮ Number of bars: The item features 8 bars.

✮ Working Width: The available working widths are 130, 190, and 220 inches.

✮ Take-up Manner: The take-up manner of this product is separately-standing.

✮ Relevant corollary equipment: Complementary equipment can include a warping machine, elastic yarn take-up, knotting, and electronic guiding yarn system.

|

型号

Machine type

|

外型尺寸(长X宽X高)

Machine size

|

全机重量

(Kg)

Machine weight

|

全机重量电机功率(KW)Motor power |

转速speed(rpm)

(横列/分钟)

|

| 主电机Main motor |

慢动电机Inching molor |

| SROP-135 |

4300X2200X2700 |

约4700 |

3 |

0.37 |

200-600 |

| SROP-150 |

4900x2200x2700 |

约5000 |

4 |

0.37 |

200-600 |

| SROP-170 |

5800x2400x2800 |

约7500 |

5.5 |

0.75 |

200-600 |

| SROP-220 |

7300x2400x2800 |

约9000 |

5.5 |

1.5 |

200-600 |

| SROP-240 |

7600x2400x2800 |

约10500 |

5.5 |

1.5 |

200-600 |

| SROP-260 |

8100x2400x2800 |

约11000 |

7.5 |

1.5 |

200-600

|

Applications:

The Double Needle Bar Raschel Machine DRCP is an application used for various nets, such as nets for sports, protective nets and packaging nets. It is very versatile and can be used for different purposes.

Uses of this application include, but are not limited to, creating sports nets, protective nets, and packaging nets. It can also be used in various other fields as well, since it is extremely versatile.

Support and Services:

Technical Support and Service for Fishing Net Making Machine

We provide technical support and service for Fishing Net Making Machine, which includes:

- On-site installation and commissioning

- Technical training of operators

- Regular maintenance and overhaul

- Provide spare parts and accessories

- 24-hour technical support hotline

- Remote fault diagnosis and repair services

Packing and Shipping:

Usually 40HQ container is used for shipment, and the engineer plans the space inside the container reasonably.

Additional accessories will be shipped in standard wooden boxes to ensure that the accessories are complete and in good condition.

Fishing Net Making Machine FAQ

1. What is the output of fishing net making machine?

It’s according the machine working width and net technical,it is about 500-1000KG/24h.

2. How much space needed to set up a fishing net production line?

The amount of space needed to set up a fishing net production line can vary depending on the size and complexity of the production line. generally, a production line for fishing nets requires 200m2.

3. What are the benefits of using a knotless fishing net making machine?

Using a fishing net making machine offers several advantages, including:

Increased Production: Machines work faster and can produce a larger volume of nets in a shorter time.

Consistency: Machine-produced nets have uniform quality and dimensions.

Reduced Labor: Automation reduces the need for manual labor, cutting down on workforce requirements.

Precision: Machines ensure accurate knotting and mesh spacing, improving net performance.

Cost-Efficiency: Over time, the machine's higher production output can lead to reduced production costs per net.

4. Are the machines customizable for different net specifications?

Yes, modern fishing net making machines are often customizable to produce nets of various sizes, mesh configurations, and materials. Adjustments can be made to the machine settings to meet specific fishing requirements.

5. What types of fishing nets can be made with these machines?

Fishing net making machines can produce a wide range of nets, including sea deep sea breeding net and small fishing net.The machine's versatility allows for the creation of nets suitable for various fishing methods and target species.

6. Are there any special skills required to operate the machine?

Operating a fishing net making machine may require some training to ensure optimal performance. Manufacturers typically provide training sessions or manuals to guide operators through the setup, operation, and maintenance of the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!