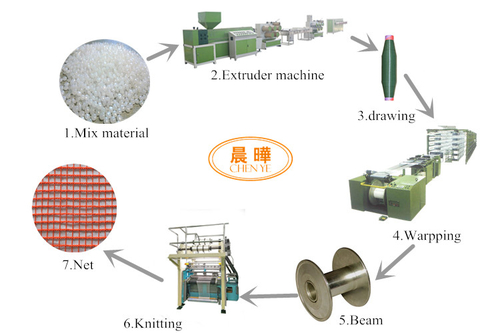

I MONO YARN EXTRUDER

The plastic wire drawing machine uses polypropylene and high-density ethylene as raw materials, which are heated, extruded and stretched to form round wires. After winding, the round wires are supplied to the circular loom for weaving. The wire drawing machine can use recycled materials, powder materials or granular materials to draw round wires. The screw and barrel of the extruder are made of 38CrMoAlA alloy steel. After nitriding, the hardness reaches above hv950. Generally, the raw wire drawing machine consists of these parts: 1. Screw, 2. Round wire head mold, 3. Cooling water tank, 4. Tractor, 5. Hot water tank, 6. Tractor, 7. Oven, 8. The third tractor, 9. Winder

II Bobbin

The bobbin is usually a galvanized iron pipe, which serves as a link between the previous and the next. The last step of the extruder winds the yarn produced by the extruder on the bobbin, the bobbin is placed on the creel, and the yarn on the bobbin is connected to the warp knitting machine

III WARPING MACHINE

After the yarn is led out from the bobbin on the creel, it is wound onto the drum one by one through the guide rod, rear reed, guide rod, photoelectric broken end self-stop piece, split reed, fixed reed, length measuring roller and guide roller. During shaft reversing, all the warp yarns on the drum exit counterclockwise with the rotation of the weaving shaft according to the double dotted line, and then roll onto the beam.

IV BEAM

Textile machine accessories are used for winding yarn and for warp knitting machine to transport yarn for weaving

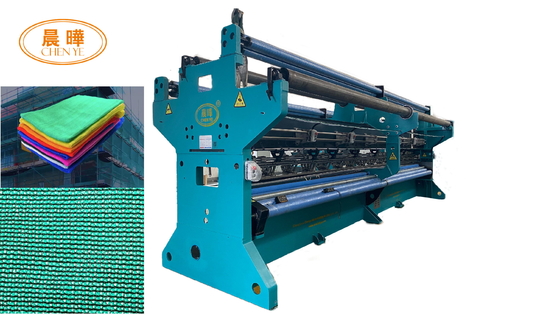

V WARP KNITTING MACHINE

Machines that use threads to weave into nets

During the loop forming process, the yarn guide needle swings back and forth between the knitting needles, and traverses before and after the needle according to the requirements of the weave pattern, so as to wrap the yarn around the knitting needle that stops at the highest position. When the knitting needle is lowered, the grid-shaped knock-off plate will hold up the old loops of the fabric, so that the old and new loops can be interlaced into a loop. When the knitting needle rises, it mainly relies on the downward pulling force of the fabric and the blocking of the bottom surface of the sinker to keep the old loop at the original height and ensure that the old loop is relatively slipped from the needle hook to the needle bar. Usually flat yarn net making machine is relatively simple, 2-4 bars can meet the weaving requirements

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!