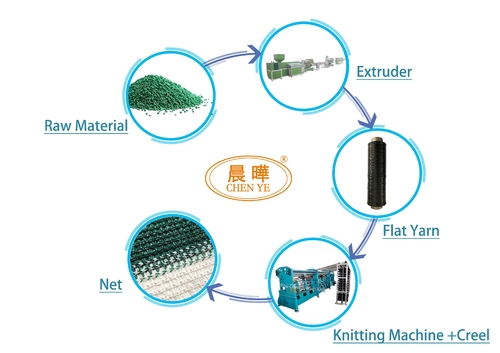

I EXTRUDER

The plastic extruder uses polypropylene and high-density ethylene as raw materials, and is heated, extruded, slit and stretched to form flat yarns, which are then wound for warp knitting machine. The wire drawing machine has generally been improved many times, and can use 100% recycled material, powder or granular material to draw flat wire. The screw and barrel of the extruder are made of 38CrMoAlA alloy steel. After nitriding, the hardness reaches Hv950 or more. The standard achieved is that the extruder is made of hard gear reducer made of 20CrMnTi alloy steel, the sprocket is made of 45# medium carbon steel after high-frequency quenching, the traction roller is electroplated with hard chrome, and the traction mechanism is increased by self-control tension. The discharge barrel, tee and film head are heated by cast aluminum heating ring, so as to be durable

II Bobbin

The bobbin is usually a galvanized iron pipe, which serves as a link between the previous and the next. The last step of the extruder winds the yarn produced by the extruder on the bobbin, the bobbin is placed on the creel, and the yarn on the bobbin is connected to the warp knitting machine

III CREEL

The creel is divided into two rows and erected on both sides of the machine in a linear or circular shape, and the yarn bobbins are inserted obliquely on the creel of the creel. The floor creel covers a large area and has a long yarn feeding distance, but the machine has a small load-bearing capacity and is convenient for yarn changing.

IV WARP KNITTING MACHINE

Machines that use threads to weave into nets

During the loop forming process, the yarn guide needle swings back and forth between the knitting needles, and traverses before and after the needle according to the requirements of the weave pattern, so as to wrap the yarn around the knitting needle that stops at the highest position. When the knitting needle is lowered, the grid-shaped knock-off plate will hold up the old loops of the fabric, so that the old and new loops can be interlaced into a loop. When the knitting needle rises, it mainly relies on the downward pulling force of the fabric and the blocking of the bottom surface of the sinker to keep the old loop at the original height and ensure that the old loop is relatively slipped from the needle hook to the needle bar. Usually flat yarn net making machine is relatively simple, 2-4 bars can meet the weaving requirements

https://www.netmakingmachine.com/supplier-371346-shade-net-making-machine

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!